Powder Coating Systems

POWDER CAOTING SYSTEM

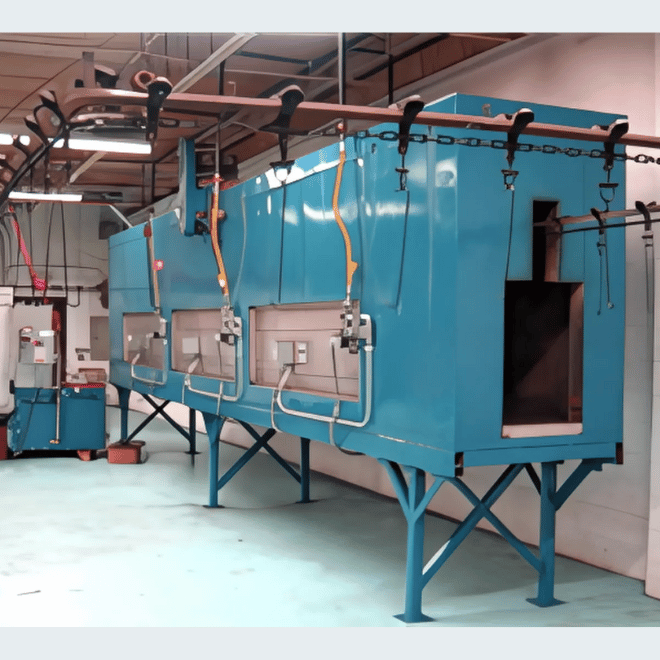

The chamber is designed according to component size and production rate. For smaller and dissimilar components open type chamber is suggested. For higher production rate material conveying systems is used. We provide all types of material handling and conveying system to suit the exact requirement.

POWDER CAOTING SYSTEM

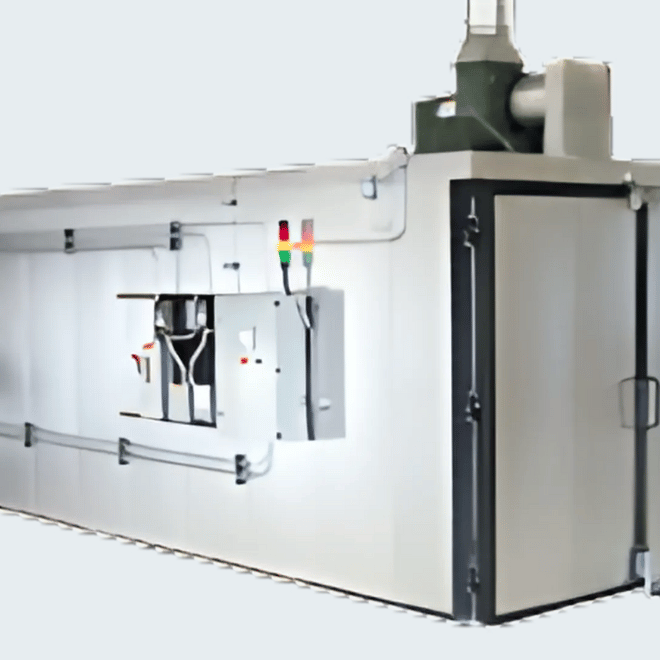

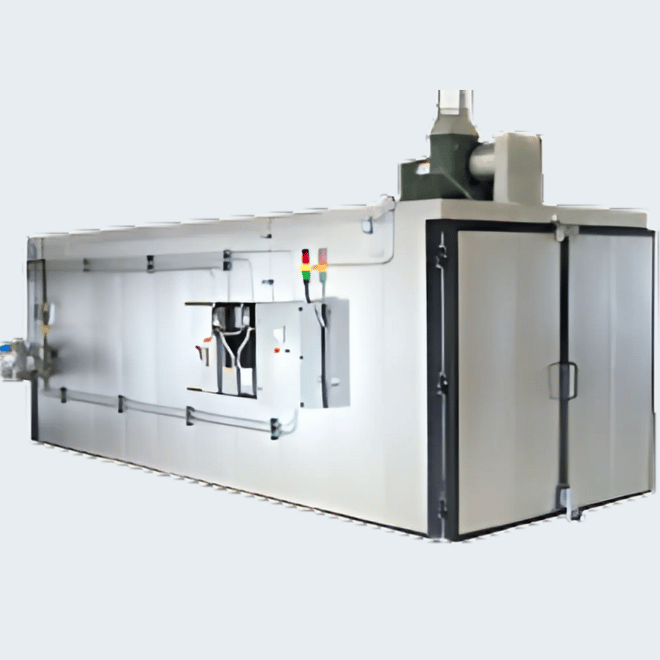

Our Hi-tech Powder Coating Systems are engineered to handle a variety of part shapes and sizes. Systems include the latest in Powder spray gun system, powder recovery system, material handling, curing oven. Hi-tech powder coating systems is equipped with advanced powder spray gun system for smooth and even powder coating with minimum powder wastage. Automated powder control system provides you right quantity of powder at required velocity. We provide special nozzle for wide coverage.

POWDER CAOTING SYSTEM

We provide bag filter system for powder recovery. The powder partials are collected in the bag and only air is exhausted into atmosphere which enhance operator comfort and environmental friendly system. Depends upon production requirements, Powder Coating Systems can utilize curing ovens. We use Infrared (IR), Gas/oil burner, electric heating elements in ovens. To allow greater flexibility and throughput, we use Infrared (IR), Gas/oil burner, electric heating elements in ovens.

Salient Features & Benefits

* EffectivecCollection and Re-use of Powder.

* Energy efficient design.

* Improved working environmental condition.

* Rust free enclosure using galvenized steel construction.

* Maximum lighting to ensure defect free powder application.

* All blower & fans are dynamically balanced to noise, vibration & trouble free operation.

* Easy cleaning of filters.

* Safety interlocks.