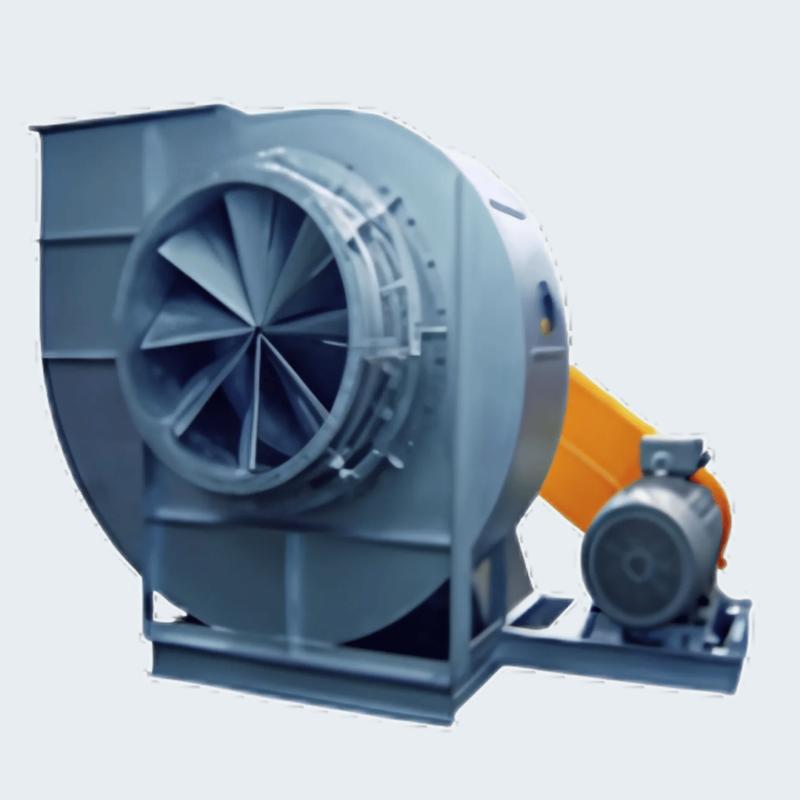

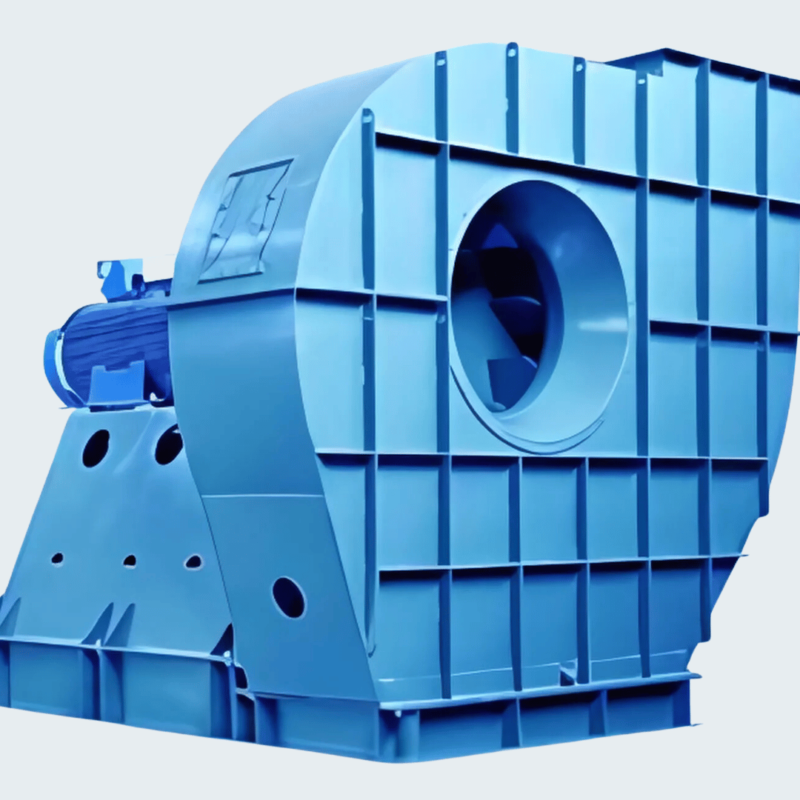

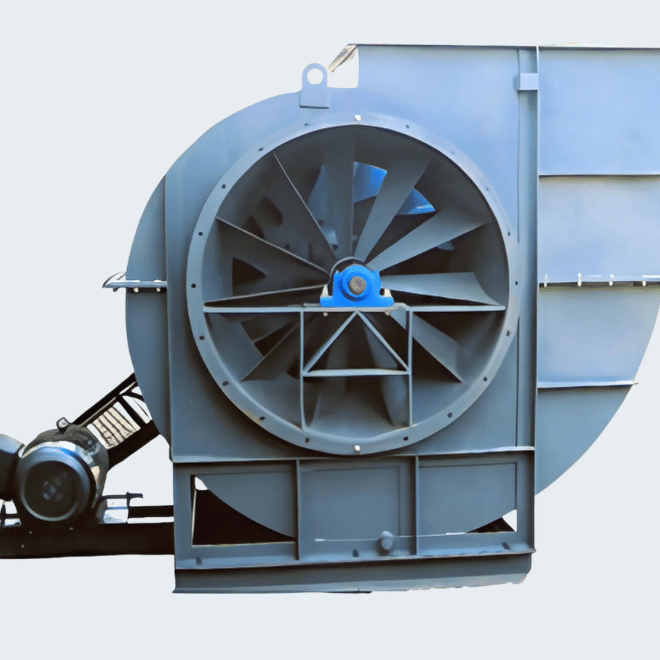

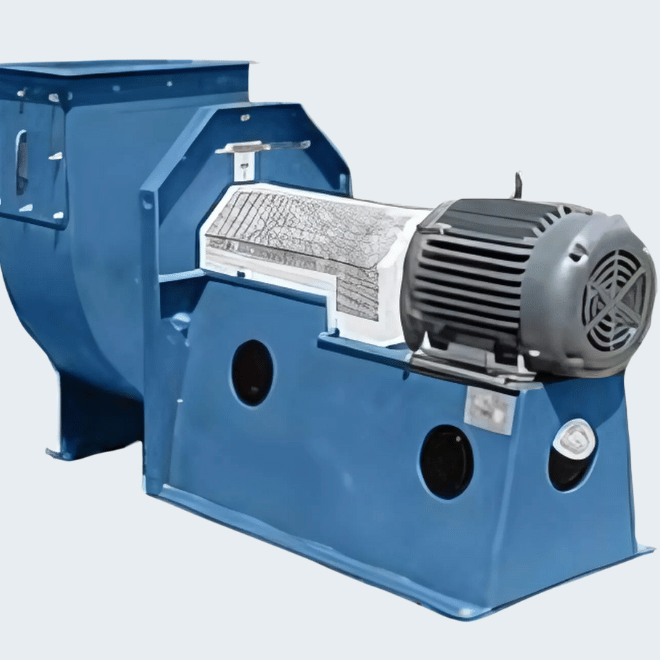

CENTRIFUGAL BLOWER

We offer

wide ranges of blowers

with various air volume and pressure combination, to suit your requirement. Our Centrifugal blowers are designed for energy efficient and high performance operation.

All impellers are dynamically balanced as per ISO 1940/1-1986 G6.3 standard for vibration free smooth running. Performance characters like noise, vibration, Air volume, Pressure, Current drawn, bearing temperature, etc., are tested for all blowers.

Technical Specification

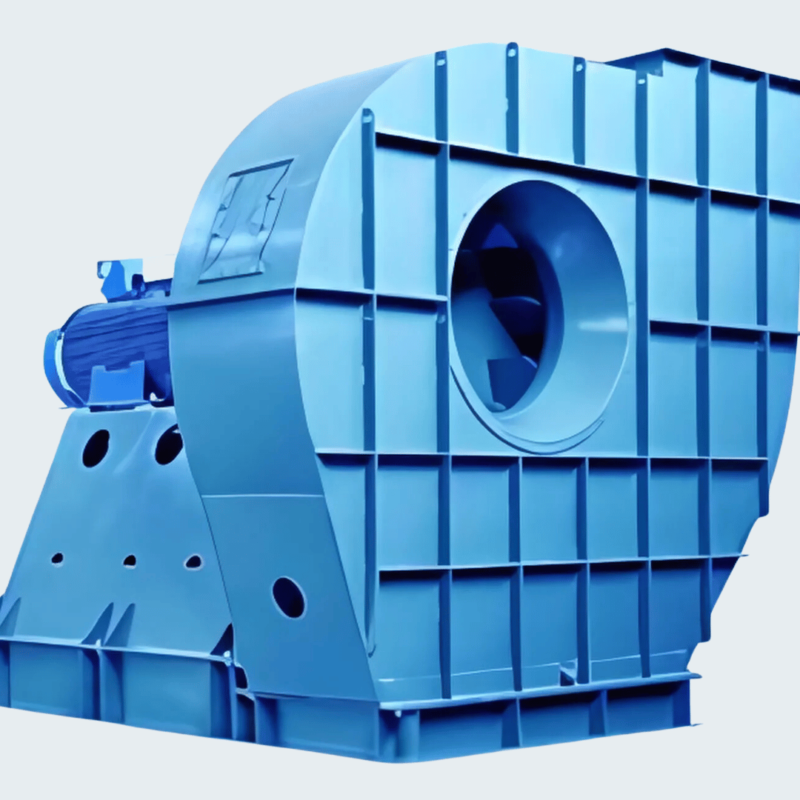

| Air/gas quantity | Upto 2,00,000 m³/hr |

| Pressure | Upto 1,500 mm WG |

| Temperature | Ambient to 380° C with cooling disc. |

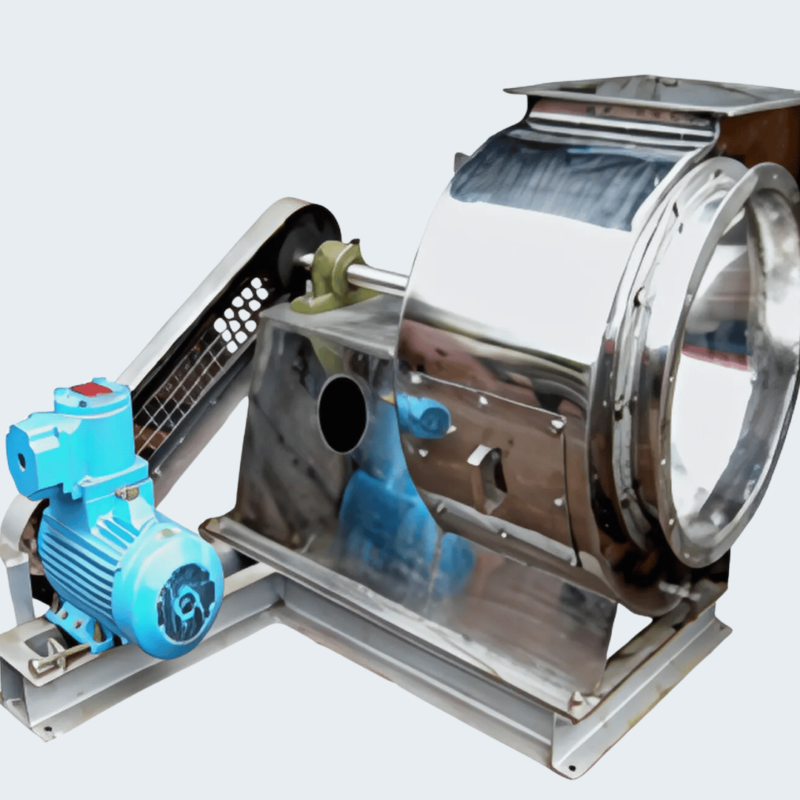

| Material of construction | MS, Graded steel, SS, FRP, PVC, PP, Rubber lined etc. |

| Impeller Type | Forward curved blades Backward curved blades Radial blades |

| Capacity | From fraction up to 300 HP |

| Direction of rotation | Clockwise or anticlockwise viewed from drive end |

| Drive | Direct drive, Coupled drive and Belt drive |

| Inputs | Electricity 220/415V±10%, 50/60 Hz, 1/3 phase |

| Finishing | Painting, Powder coating or Plating |

Applications

Drugs & Pharmaceuticals, Hospitals, Cement, Steel Plant,Foundries, Chemical Distilleries, Rice Mill, Boilers, Foundries, Welding Shops, Pharmaceuticals, Chemical industries, Automobile industry, Hotel Industries, Air Conditioning, Ventilation, Pressurization, Pneumatic Conveying, water treatment (Degasser blower) and other allied industries and applications.

Features & Benefits

* Compact design, rugged construction

* Low noise and vibration

* Highly efficient aerofoil design

* Low and easy maintenance

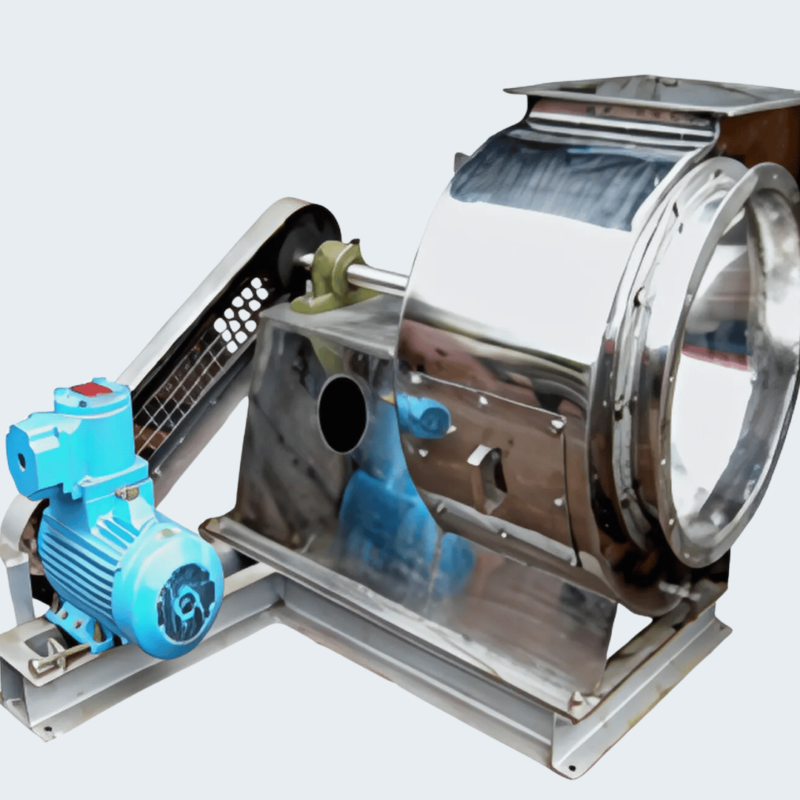

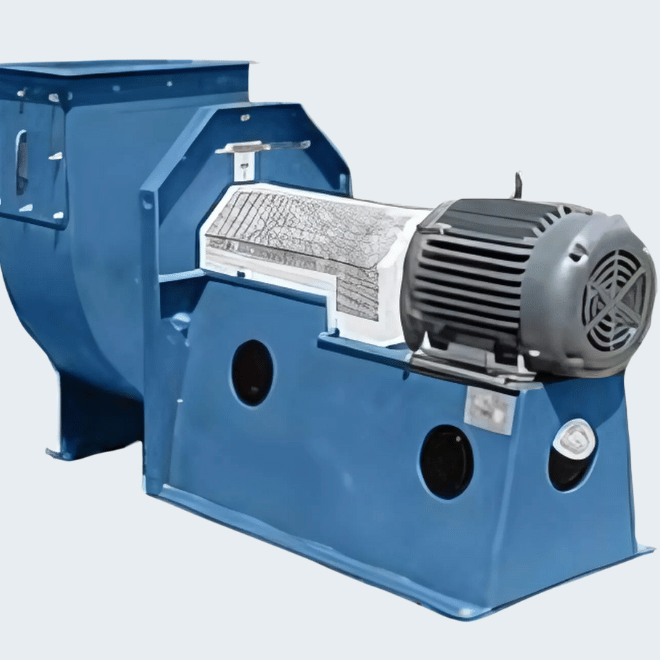

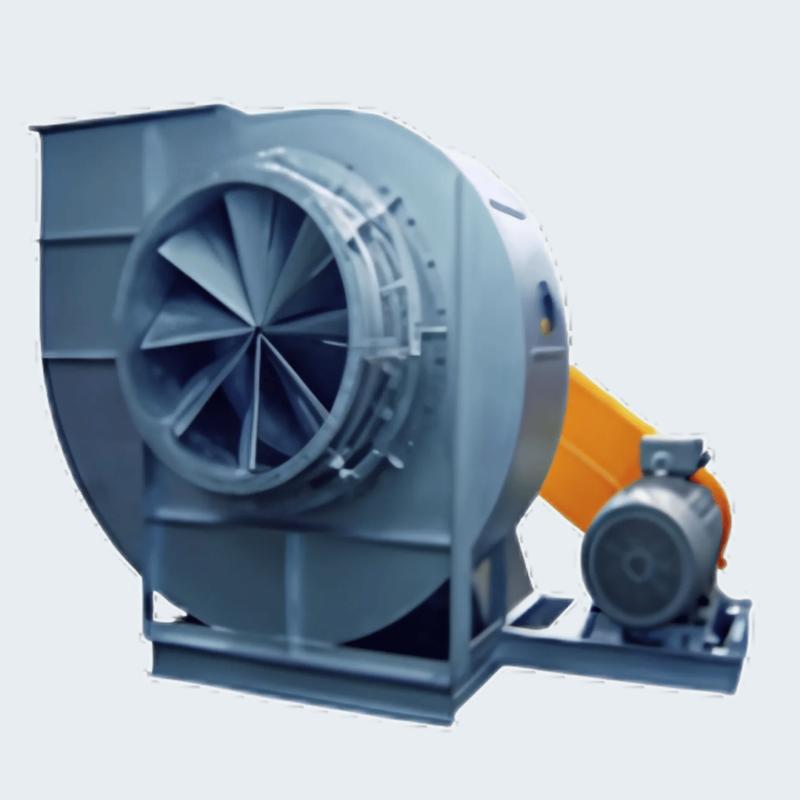

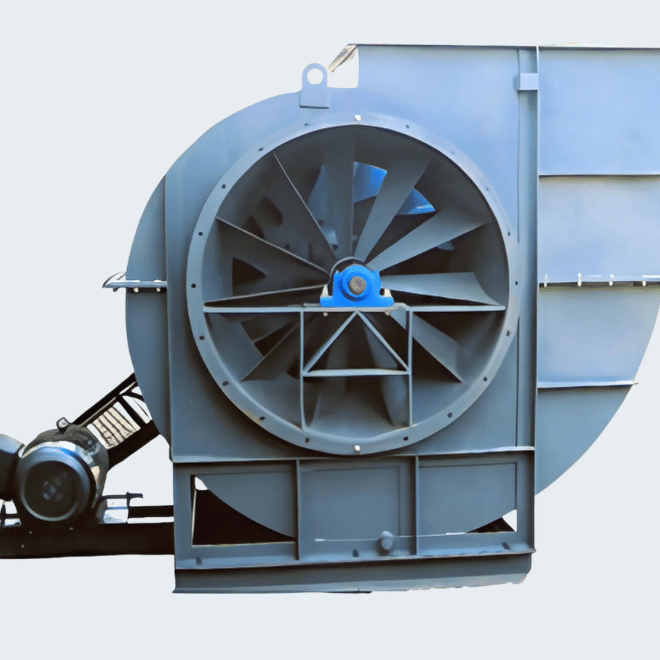

CENTRIFUGAL BLOWER

We offer

wide ranges of blowers

with various air volume and pressure combination, to suit your requirement. Our Centrifugal blowers are designed for energy efficient and high performance operation.

All impellers are dynamically balanced as per ISO 1940/1-1986 G6.3 standard for vibration free smooth running. Performance characters like noise, vibration, Air volume, Pressure, Current drawn, bearing temperature, etc., are tested for all blowers.

Technical Specification

| Air/gas quantity | Upto 2,00,000 m³/hr |

| Pressure | Upto 1,500 mm WG |

| Temperature | Ambient to 380° C with cooling disc. |

| Material of construction | MS, Graded steel, SS, FRP, PVC, PP, Rubber lined etc. |

| Impeller Type | Forward curved blades Backward curved blades Radial blades |

| Capacity | From fraction up to 300 HP |

| Direction of rotation | Clockwise or anticlockwise viewed from drive end |

| Drive | Direct drive, Coupled drive and Belt drive |

| Inputs | Electricity 220/415V±10%, 50/60 Hz, 1/3 phase |

| Finishing | Painting, Powder coating or Plating |

Applications

Drugs & Pharmaceuticals, Hospitals, Cement, Steel Plant,Foundries, Chemical Distilleries, Rice Mill, Boilers, Foundries, Welding Shops, Pharmaceuticals, Chemical industries, Automobile industry, Hotel Industries, Air Conditioning, Ventilation, Pressurization, Pneumatic Conveying, water treatment (Degasser blower) and other allied industries and applications.

Features & Benefits

* Compact design, rugged construction

* Low noise and vibration

* Highly efficient aerofoil design

* Low and easy maintenance